Norway New Robotic Hub to Accelerate Hydrogen Tech Manufacturing

Norway has taken a pioneering leap in clean energy engineering with the recent launch of Provaris Energy’s advanced Robotics Innovation Centre in Fiskå. This state-of-the-art facility is designed to transform the manufacturing of hydrogen and liquid CO2 storage tanks, accelerating the development of green hydrogen supply chains for Europe and Asia.

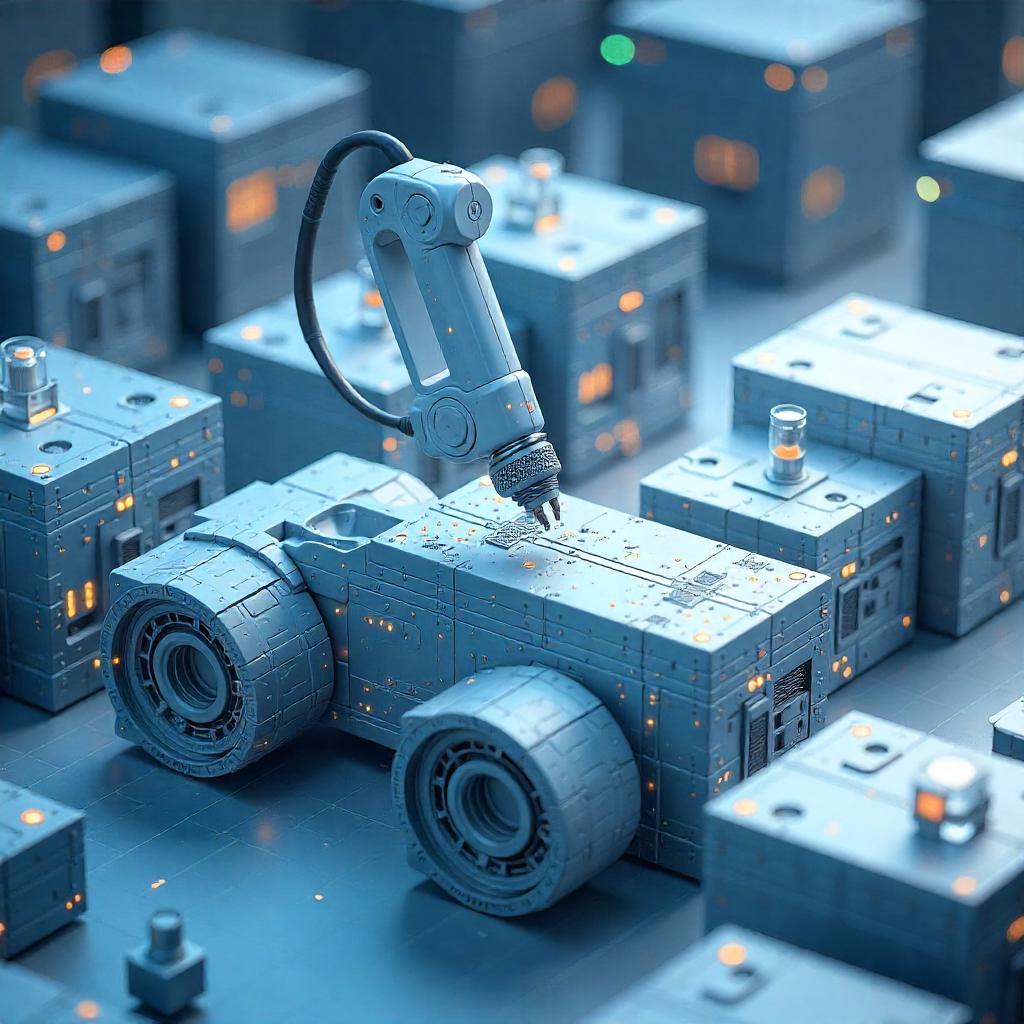

At the heart of the Innovation Centre is a fully automated robotic cell fitted with advanced robotic arms, controllers, scalable jigs, and laser-hybrid welding systems. This integration of robotics not only streamlines fabrication but also achieves levels of precision, scalability, and cost efficiency previously unattainable in large-scale industrial tank production. Provaris is now restarting work on its proprietary hydrogen prototype tank, which is expected for testing in Q1 2026—a critical milestone for the company’s flagship compressed hydrogen shipping solution, the H2Neo™ bulk carrier.

The hydrogen prototype tank, once completed, will be an engineering marvel—measuring 11 meters long, 2.5 meters in diameter, and weighing about 40 tonnes. Through laser-hybrid welding and agile robotic automation, Provaris aims to dramatically reduce construction costs while improving the quality assurance standards required for maritime and industrial certification. The company is simultaneously using the Centre to advance its LCO₂ tank projects, with strong demand coming from the carbon capture and storage (CCUS) sector across Europe.

Provaris CEO Martin Carolan underscored the strategic role of the centre: not only showcasing the efficiency benefits of robotics in tank manufacturing but establishing Provaris as a reliable supplier for the global hydrogen economy. The Norwegian facility is already attracting interest from international shipping leaders, who will visit the Innovation Centre later this year to observe the fabrication process first-hand—a clear sign of the growing industry recognition for compressed hydrogen shipping solutions.

By 2026, maritime Class approvals are expected to green-light Provaris’s tank designs for full-scale commercial hydrogen transport. The company’s adaptive strategy extends to front-end engineering and pilot tank fabrication for its LCO₂ joint venture with Yinson Production, ensuring its technology platform is relevant in both hydrogen and CO₂ value chains.

As the race to decarbonise heavy shipping and industry intensifies across Europe and Asia, Norway’s new robotic hub is set to play a vital role. By leveraging the strengths of automation, modular design, and strategic industry partnerships, Provaris is positioning itself at the centre of the hydrogen transition, making large-scale clean energy transport both achievable and affordable.